Briquetting Machine Manufacturers & Suppliers in India

Transform your metal waste into valuable resources with Super Recycling’s premium briquetting machines. As leading briquetting machine manufacturers in India, we specialize in designing and supplying high-performance vertical and horizontal briquetting machines for ferrous and non-ferrous metal recycling. Our advanced briquetting technology helps industries reduce waste volume by up to 90%, maximize storage efficiency, and increase melting furnace productivity.

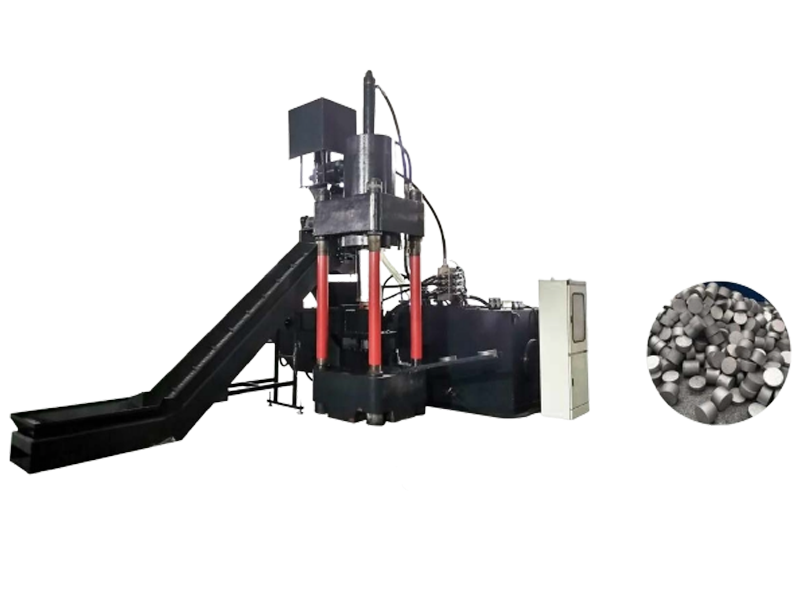

A Briquetting machine for ferrous and non-ferrous metal swarf and turnings is an essential piece of equipment in the metal recycling industry. It transforms your waste into value with our high-performance Briquetting Machine — engineered to compress loose materials into dense, durable briquettes that save space, reduce handling costs, and boost operational efficiency. These machines are designed to compact metal chips, swarf, and turnings into dense, cylindrical briquettes.

Briquetting machines come in various sizes and capacities, suitable for different scales of operation, from small workshops to large industrial facilities. They help in conserving resources, promoting sustainability, and maximizing profit by reclaiming valuable metal content that would otherwise be lost.

Technical Specifications

VERTICAL BRIQUETTING MACHINE | ||

MAX FORCES | 315 TONS TO 630 TONS | PARAMETERS ARE CUSTOMIZABLE ACCORDING TO THE CLIENT’S REQUIREMENT. |

PRODUCTION OUTPUT | 1 TONS TO 6 TONS PER HOUR | |

MATERIAL | CI, SS, AL. CU. BRASS | |

MACHINE OPERATIONS | PLC AND REMOTE CONTROLLED | |

HORIZONTAL BRIQUETTING MACHINE | ||

MAX FORCES | 1000 TONS TO 3000 TONS | PARAMETERS CUSTOMIZABLE ACCORDING TO THE CLIENT’S REQUIREMENT. |

PRODUCTION OUTPUT | 14 TONS TO 50 TONS PER HOUR | |

MATERIAL | CI, SS, AL. CU. BRASS | |

MACHINE OPERATIONS | PLC AND REMOTE CONTROLLED | |

Request A Call Back

What is a Briquetting Machine? Working Principle Explained

Working of Briquetting Machine

A briquetting machine is an industrial equipment that compresses loose metal chips, swarf, and turnings into dense, cylindrical briquettes through hydraulic pressure. The working of briquetting machine involves four key stages:

Stage 1: Material Loading – Metal chips and swarf are fed into the machine’s compression chamber through an automated feeding system.

Stage 2: Compression Process – Hydraulic cylinders apply tremendous force (315-3000 tons) to compress the loose material into compact briquettes.

Stage 3: Briquette Formation – The compressed material forms dense, cylindrical briquettes with 8-12 times higher density than loose chips.

Stage 4: Ejection – Finished briquettes are automatically ejected from the machine, ready for storage or direct melting.

This process eliminates coolant waste, reduces transportation costs, and increases melting efficiency by 25-30%.

Briquetting Machine Diagram & Technical Components

Briquetting Machine Diagram

Our briquetting machines feature robust construction with key components designed for maximum efficiency:

Main Components Illustrated in Briquetting Machine Diagram:

1. Hydraulic Power Unit – Generates compression force from 315 to 3000 tons

2. Compression Chamber – Where metal chips are compacted into briquettes

3. Material Feeding System – Automated conveyor for continuous operation

4. PLC Control Panel – Touch-screen interface for precise operation control

5. Briquette Ejection System – Automatic discharge mechanism

6. Hydraulic Cylinders – Primary and secondary compression cylinders

7. Safety Systems – Emergency stops and protective barriers

The briquetting machine diagram clearly shows the material flow from feeding to final briquette ejection, ensuring operators understand the complete process cycle.

Briquetting Machine Price & Models

Competitive Briquetting Machine Price Structure

We offer transparent pricing for all our briquetting machine models. Our briquetting machine price varies based on capacity, force rating, and customization requirements:

Vertical Briquetting Machine Price Range:

a) 315 Ton Capacity: Upto ₹30 Lakhs

b) 450 Ton Capacity: Upto ₹50 Lakhs

c) 630 Ton Capacity: Upto ₹1 Crore

Price Includes:

a) Complete machine installation

b) Operator training program

c) 12-month comprehensive warranty

d) 24/7 Technical support and maintenance

Note: Prices may vary. Please connect with our team to get the final Briquetting Machine price quote

Why Choose Super Recycling as Your Briquetting Machine Suppliers?

Leading Briquetting Machine Suppliers in India

As trusted briquetting machine suppliers, Super Recycling offers comprehensive solutions for metal recycling industries:

Our Competitive Advantages:

a) 13+ Years Manufacturing Experience – Proven track record in industrial equipment

b) Customization Capability – Machines tailored to specific industry requirements

c) Pan-India Service Network – Local support across major industrial hubs

d) Quality Certifications – ISO certified manufacturing processes

e) Comprehensive Warranty – 12-month parts and service warranty

f) Training & Support – Complete operator training and technical support

Industries We Serve:

a) Automotive manufacturing and machining

b) Steel and aluminum processing plants

c) Metal fabrication workshops

d) Foundries and casting units

e) Scrap metal recycling facilities

Benefits of Our Briquetting Machines

Return on Investment Benefits

a) Space Savings: Reduce storage space requirements by 85-90%

b) Transportation Cost Reduction: Lower shipping costs due to increased density

c) Melting Efficiency: 25-30% faster melting in furnaces

d) Revenue Generation: Convert waste into sellable briquettes

e) Environmental Compliance: Reduce waste disposal costs and environmental impact

Operational Advantages

a) Automated Operation: PLC-controlled systems reduce manual labor

b) High Reliability: Robust construction ensures 99%+ uptime

c) Easy Maintenance: Accessible components for quick servicing

d) Safety Features: Comprehensive safety systems protect operators

e) Energy Efficiency: Optimized hydraulic systems minimize power consumption