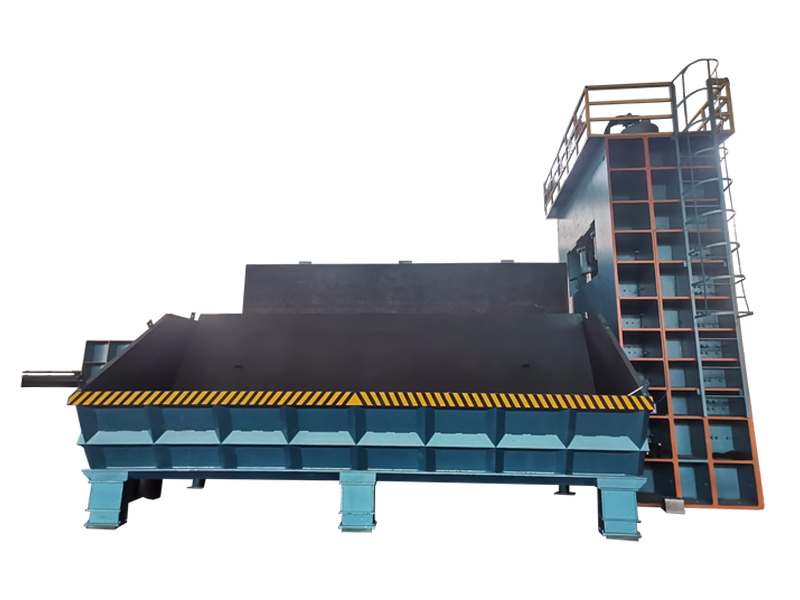

Vertical Heavy-Duty Scrap Shear Machine

A heavy-duty scrap shear is a powerful and versatile machine used for many tasks. It can cut different types of scrap, such as lightweight steel parts, low-carbon materials, old vehicles, and metal structures. It’s perfect for cutting large metal pieces and steel profiles that are ready to be used as furnace charge.

Heavy-duty shear machines are vital instruments in the metal recycling sector, designed to effectively cut waste steel, angle steel, round steel, steel plate, H steel, stainless scrap, copper, and aluminum profiles, and all kinds of ferrous and non-ferrous metals, etc. Available in a range of models, these machines cater to different operational requirements.

Heavy-duty vertical shears are built for high-volume operations, enabling a continuous material feed that boosts productivity and efficiency. In contrast, vertical shears, including box shears and gantry shears, provide both versatility and precision, delivering accurate cuts for various scrap sizes. Gantry shears, known for their sturdy construction, excel at managing large and heavy scrap metals, offering impressive cutting force and durability. Both types of shearing machines are essential for enhancing the recycling process by reducing metal to manageable sizes, making transport and further processing easier.

Technical Specifications

Shearing Cutting Force | 400 Tons to 1250 Tons | Parameters are customizable according to the client’s requirements. |

Feeding Box | 6000 MM TO 8000 MM | |

Production Capacity | 4 Tons to 40 Tons per hour | |

Blade Length | 1400 MM TO 2500 MM | |

INCLUDING ESSENTIALS | Hydraulic Pusher LID Automatic Regenerative System Heat Exchanger PLC & Remote Controlled |

Request A Call Back

Vertical Heavy Duty Scrap Shear Machines for Metal Recycling

At Super Recycling Solutions, we specialize in advanced machinery designed for high-volume recycling yards, steel mills, and metal processing facilities. Our vertical heavy-duty scrap shear machine range is built for maximum durability, precise cutting, and consistent performance in the most demanding environments.

Why Choose a Heavy Duty Vertical Shear?

A heavy-duty vertical shear is engineered to handle oversized scrap, structural steel, and mixed metal waste that standard machines cannot process efficiently. The vertical design offers stability and allows operators to feed large materials directly into the workbin. This makes a vertical scrap shear ideal for facilities dealing with high volumes of heavy scrap.

Hydraulic Scrap Shear Technology

Advanced hydraulic scrap shear systems power all of our machines. Hydraulic drive ensures smooth operation, high cutting force, and reduced maintenance compared to mechanical systems. Depending on your needs, we offer machines with cutting forces from 600 tons up to 1,200 tons, giving you the flexibility to choose the right model for your scrap load.

Gantry Shear Machine vs Guillotine Scrap Shear

We provide both gantry shear machines and guillotine scrap shears.

A gantry shear machine is ideal for continuous production, with a robust frame and automatic feeding capability.

A guillotine scrap shear uses a downward blade action, making it highly effective for cutting long steel sections, sheet metal, and large profiles with precision.

Our experts can help you determine which model best fits your operation.

Key Features of Our Metal Cutting Shears

Metal cutting shear vertical design for maximum efficiency in limited floor spaces.

Industrial metal shear machine frames are made with high-strength steel for long service life.

Vertical sheet metal shear configuration for clean and accurate cuts.

Adjustable cutting force (tons) to match specific production demands (e.g., 800-ton, 1000-ton, 1200-ton shears).

Optimized blade length / cutting width to handle everything from rebar and plate steel to mixed scrap bundles.

Large feeding box / workbin size, designed to accept bulky scrap without pre-processing.

Scrap Metal Shearing Machine for Every Application

Whether you are processing HMS scrap, car bodies, non-ferrous metals, or structural steel, our scrap metal shearing machines are engineered to deliver:

High throughput for recycling yards

Consistent cut size for easy downstream handling

Low energy consumption with hydraulic efficiency

Safety systems compliant with international standards

Partner with Super Recycling Solutions

With 13 years of experience in supplying and maintaining recycling equipment, Super Recycling Solutions provides more than just machinery. We deliver full installation support, operator training, and after-sales service to keep your vertical heavy-duty scrap shear machine performing at its best.

If you are looking for a reliable solution to improve productivity and reduce scrap handling costs, our team can guide you to the right machine based on cutting force, blade length, and feeding box size.

Related Solutions for Scrap Processing

At Super Recycling Solutions, our expertise goes beyond vertical heavy-duty scrap shear machines. We provide a complete line of recycling and processing equipment to help facilities maximize output and minimize waste.

For compacting bulky scrap into transport-friendly bundles, our Scrap Baler Machines offer high compaction ratios and reliable performance.

If you handle metal chips, swarf, or fine scrap, a Briquetting Machine is an efficient way to reduce volume while recovering valuable cutting fluids.

For size reduction of mixed materials, our Dual Shaft Shredder provides powerful shredding action and long service life.

To keep your machinery running smoothly, our Hydraulic Oil Filtration Systems help maintain fluid quality, reduce wear, and extend equipment lifespan.

By combining these machines with a scrap shear, you can build a fully integrated recycling line that boosts productivity and lowers operating costs.

Ready to Upgrade Your Recycling Operation?

Contact Super Recycling Solutions today to discuss your requirements. Our specialists will help you select the right hydraulic scrap shear, gantry shear, or guillotine shear that matches your production scale and budget.